Honeywell, a global leader in technology and manufacturing, has announced a significant partnership with Beijing Hinergy Qingyuan Technology Co Ltd (Hinergy) to accelerate plastic recycling efforts in China. As part of this collaboration, Hinergy will deploy Honeywell’s innovative UpCycle Process Technology in a new recycling facility located in Shandong Province.

The facility, which is expected to process 30,000 tons of mixed waste plastics annually, will utilise Honeywell’s UpCycle Process Technology to convert waste plastics into recycled polymer feedstock (RPF). This advanced technology reduces the need for fossil fuel-derived virgin plastics and is a key component in addressing the global challenge of plastic waste.

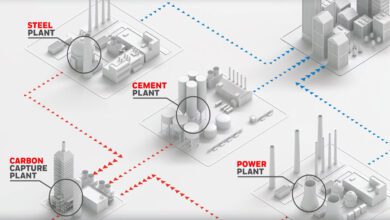

Honeywell’s UpCycle Process Technology uses cutting-edge molecular conversion, pyrolysis, and contaminants management processes to transform a wide range of plastic types—including coloured, flexible, multilayered packaging and polystyrene—into RPF. When combined with other recycling processes and enhanced collection and sorting methods, the technology has the potential to recycle nearly 90% of waste plastics, significantly boosting the amount of plastic waste that can be repurposed into new products.

“Hinergy is fully committed to technological development and project construction in China’s environmental protection industry,” said Chen Donglin, Chairman of Hinergy. “With the accelerated global carbon reduction process and national support for the circular economy, we are confident in the future market prospects for recycling plastic waste. Through cooperation with Honeywell, Hinergy will leverage the company’s UpCycle Process Technology to establish our first waste plastic recycling facility and further contribute to China’s circular plastics economy.”

This collaboration aligns with Honeywell’s broader focus on the energy transition, one of the three key megatrends shaping its portfolio, along with automation and the future of aviation. Honeywell’s UpCycle technology plays a crucial role in closing the loop within the plastics supply chain by reducing the carbon footprint associated with plastic production.

“Honeywell’s UpCycle Process Technology broadens the types of plastics that can be recycled, helping to close the loop within the plastics supply chain with a lower carbon footprint,” said William Yu, President of Honeywell China. “We are pleased to collaborate with Hinergy to promote the commercial application of UpCycle, helping to address challenges in traditional plastic waste recycling and contributing to China’s sustainable development goals.”

As part of the partnership, Honeywell will provide its UpCycle Process Technology, along with start-up engineering and technical services to support the facility’s operations, optimisation, monitoring, and maintenance throughout its service life. This initiative is a testament to Honeywell’s commitment to environmental and social outcomes, with approximately 60% of its new product research and development focused on sustainability.