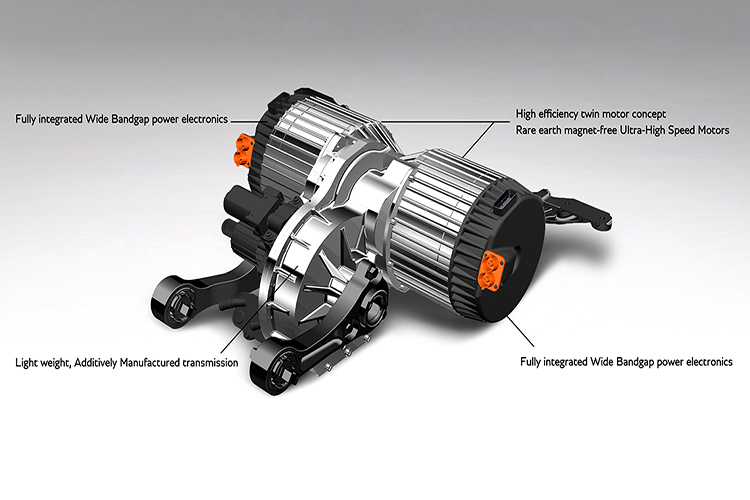

Bentley Motors announces a three-year research study that promises to transform electric vehicle powertrains, utilising a fully integrated, free from rare-earth magnet e-axle that supports electric vehicle architectures. This reinforces Bentley’s ambition to lead sustainable luxury mobility and introduce the first fully electric Bentley by 2026. The study, titled OCTOPUS (Optimised Components, Test and SimulatiOn, toolkits for Powertrains which integrate Ultra-high-speed motor Solutions) follows an initial 18-month investigation that delivered a technological breakthrough in electric drive systems for high-performance vehicles.

Building on the UK’s leading electronics research, the resulting electric drive system exceeded the latest permanent magnet motor performance while simultaneously removing the need for both rare-earth magnets and copper windings, delivering a package both cost effective and recyclable at its end of life. OCTOPUS will take this leading-edge motor, power electronics and packaging transmission design, adding next generation materials, manufacturing processes, simulation and test cycles to deliver a full e-axle powertrain with unique levels of integration and revolutionary performance characteristics suitable for real world application by 2026.

Commenting on the project, Stefan Fischer, Director of Powertrain Engineering at Bentley Motors, said, “We have made no secret of our ambition to lead the way in the delivery of sustainable luxury mobility, Beyond100. We have a clear roadmap to offer a hybrid option for every model by 2023, starting with the Bentayga Hybrid, and our next goal moves towards a fully electric Bentley by 2026. However today, there remains challenges and package constraints on the viability and flexibility of electric vehicle powertrains that are able to fully support EV architectures. With the industry, technologies and cars changing faster than ever before, research projects such as OCTOPUS are crucial to deliver innovative technologies and overcome challenges for the next generation of mobility solutions.”

OCTOPUS is an OLEV funded project delivered in partnership with Innovate UK which brings together the following partners with distinct roles and responsibilities:

Bentley Motors – Specification setting, vehicle integration plan and system test.

Advanced Electric Machines Ltd – Motor manufacturing and systems assembly.

Advanced Electric Machines Research Ltd – Motor and transmission design.

The Thinking Pod Innovations Ltd & Nottingham University – Power electronics optimisation and alternative wide band gap system design.

The Institute for Advanced Automotive Propulsion Systems (IAAPS) at the University of Bath – Integrated system analysis and proof of concept validation testing.

HiETA Technologies Ltd – AM component design and manufacture for thermal management including stator core housing, power electronics and E-axle oil cooling.

FD Sims Ltd – Next generation wire technology development.

Talga Technologies Ltd – 2D materials development for next generation winding technologies.

Diamond Light Source – UK’s national synchrotron light source providing access to X-ray facilities for measurements.

Hartree Centre (Science and Technology Facilities Council) – Advanced system testing and co-simulation toolkit development.

Francesca Ludicello, Programme Manager for low & zero emission vehicles at Innovate UK added, “The IDP Programme is playing a significant part in the UK’s push to net zero carbon by providing support for the development of ground-breaking zero emission technologies. The APEX and OCTOPUS projects are an outstanding example of how the partnership between a UK SME and a global OEM can continue through the different development stage of motor drives, which puts UK innovation at the forefront of the high performance PEMDs market worldwide.”

Advanced Electric Machines Group CEO, Dr. James Widmer, said “Having already worked closely with Bentley to successfully deliver a proof of concept, we look forward to this new project to push the performance, packaging and sustainability of electric vehicle drives to a new level, removing the need for rare-earths and copper and achieving the highest levels of system integration.”