In a groundbreaking achievement that has sent ripples through the steel industry, the Nagarnar Steel Plant has achieved a feat that defies conventional norms. The plant, operated by the National Mineral Development Corporation (NMDC), has successfully produced its first Hot Rolled (HR) Coil a mere 9 days after the commencement of Hot Metal production. This remarkable accomplishment is even more impressive considering that NMDC had no prior experience in steelmaking, marking a monumental leap for the mining giant.

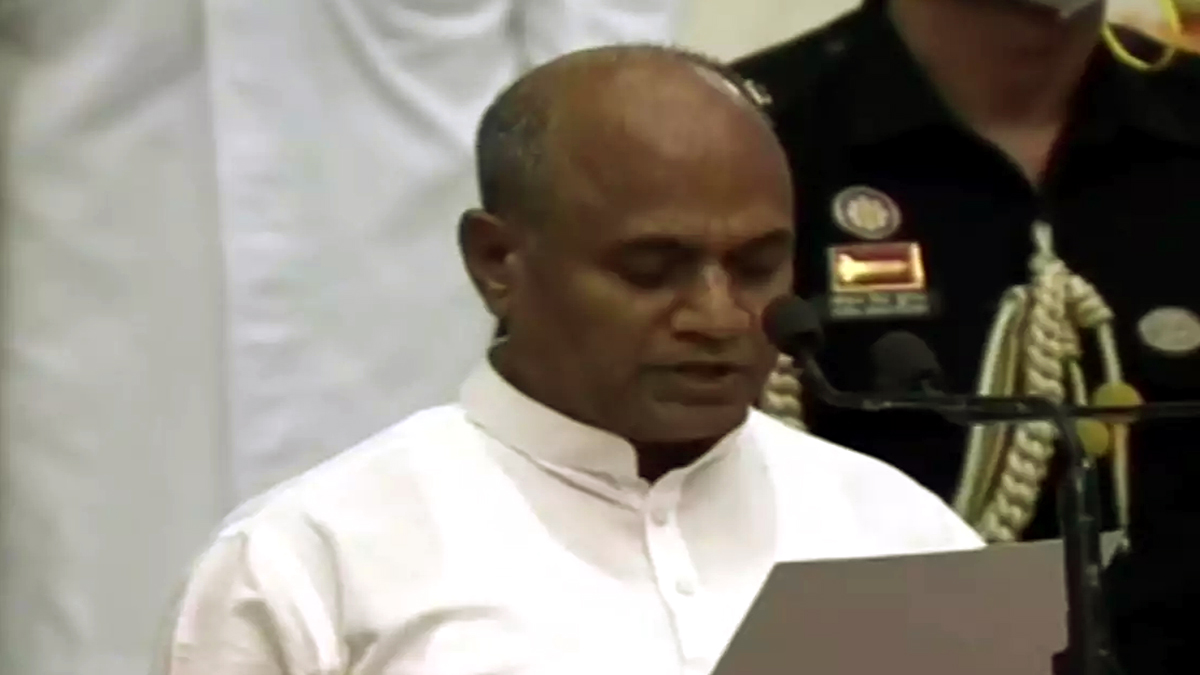

“This achievement marks NMDC’s entry into the elite group of Indian steel producers. It is the realization of a long-held aspiration of the Bastar community,” remarked Amitava Mukherjee, CMD of NMDC. Industry veterans are awestruck by the swift commissioning of three pivotal units in the high-temperature zone: the Blast Furnace, Steel Melting Shop, and the Thin Slab Caster – Hot Strip Mill – all within an exceptionally short timeframe.

With an investment of around ₹24,000 crores, the Nagarnar Steel Plant boasts a capacity of 3 million tonnes per annum. Its proximity to the Bailadila mines, which are just 100 kilometers away, underscores the plant’s strategic advantage by ensuring a seamless supply of iron ore. With its high-grade HR steel tailored to cater to various key sectors, the Nagarnar Steel Plant is ready to make a substantial impact on the Hot Rolled market.

The plant’s product portfolio encompasses low carbon steel, HSLA & Dual Phase Steel, and API quality steel, offering a thickness range from 1mm to 16mm. Distinguished by its capacity to roll HR up to 1,650 mm wide, the Thin Slab Caster stands as a testament to innovation. This state-of-the-art mill produces Hot Rolled coils, sheets, and plates that are ready to meet the increasing demand for quality HR in the production of LPG cylinders, bridges, ships, large pipes, storage tanks, and numerous industrial applications.

Additionally, a specialized steel variant vital for the fabrication of generators, transformers, motors, and automobiles in subsequent stages can be produced by the plant. The mining entity established the Nagarnar Steel Plant, creating an unparalleled distinction that sets it apart on the international stage as the only steel facility of its kind

The first Hot Rolled coil rolled out just yesterday, a mere 9 days following the initiation of hot metal production on August 15th. Industry veterans are quick to acknowledge the groundbreaking nature of this achievement. While instances of swift steel production have been recorded in the past, the Nagarnar Steel Plant’s rarity lies in its ability to produce an HR Coil within such a condensed timeframe.

Notably, the Nagarnar Steel Plant conducted cold trials of its Steel Melting Shop months before embarking on the commissioning of the blast furnace. This meticulous approach, combined with the application of cutting-edge technology and expertise, played a pivotal role in expediting the process. Typically, stabilizing the blast furnace’s operation takes weeks, followed by synchronization with the Steel Melting Shop. This delicate stage, fraught with challenges, attests to the plant’s cautious yet agile approach.