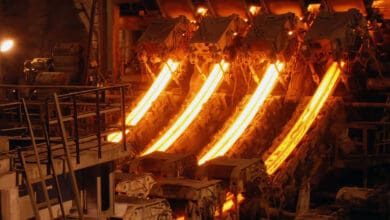

In a strategic move to enhance the utilisation of indigenous coking coal and drive the decarbonisation of India’s steel sector, the government and industry stakeholders have implemented several initiatives. Given that steel is a deregulated sector, decisions on technological advancements lie with individual companies, guided by market dynamics and techno-commercial considerations.

Coal and steel companies are actively working to expand domestic coal washing capacity to reduce ash content, making it suitable for steel production. Additionally, the adoption of stamp charged coke oven batteries in steel plants is set to enhance the use of indigenous coking coal, reducing dependency on imports.

The Ministry of Steel released a comprehensive report titled “Greening the Steel Sector in India: Roadmap and Action Plan” in 2024. The document outlines multiple pathways for reducing greenhouse gas emissions in the sector, providing an actionable strategy and roadmap for sustainable steel production.

The Production Linked Incentive (PLI) Scheme for Specialty Steel, launched in July 2021 with a budget of ₹6,322 crore, aims to promote domestic manufacturing of specialty steel, reducing imports and attracting capital investments. As of December 31, 2024, the scheme has seen a total investment commitment of ₹27,106 crore, with ₹18,850 crore already achieved. The targeted production is 7,940 thousand tonnes, of which 1,258 thousand tonnes have been achieved, including 928 thousand tonnes in FY 2024-25. In terms of employment, the scheme aims to generate 14,760 jobs, with 8,930 jobs already created. An incentive disbursement of ₹48 crore has been made, and further disbursement claims are expected in FY 2024-25. To ensure wider participation, a dedicated web portal has been launched, along with extensive media outreach and frequent webinars with interested companies.

The government has implemented several policies to curb steel imports and strengthen domestic production. Quality Control Orders have been introduced to ban sub-standard steel products, ensuring high-quality materials for industries and consumers. The Steel Import Monitoring System (SIMS 2.0), launched on July 25, 2024, enhances the monitoring of steel imports. The Domestically Manufactured Iron & Steel Products (DMI&SP) Policy encourages the use of locally made steel in government procurement. Anti-Dumping and Countervailing Duties have been imposed on various steel products from China, Korea, Japan, Vietnam, and Thailand to safeguard domestic producers from unfair trade practices.

India boasts sufficient iron ore reserves to meet domestic demand, with over 270 million tonnes produced in FY 2024. Exports stood at approximately 46 million tonnes, while imports were significantly lower at 4.9 million tonnes. To enhance mineral supply, the government has undertaken several reforms, including expediting auction and operationalisation of expired mining leases, allowing captive mines to sell up to 50% of their output, and simplifying transfer and approval processes for mining leases.

In a bid to promote sustainable practices, the Steel Scrap Recycling Policy, introduced in November 2019, provides a structured framework for scientific processing and recycling of ferrous scrap. This policy aims to reduce dependence on virgin raw materials and improve the circular economy in the steel sector.

Despite various initiatives, steel imports have seen an upward trend. As per the latest data from the Joint Plant Committee (JPC), total finished steel imports rose from 6.02 million tonnes in 2022-23 to 8.32 million tonnes in 2023-24. China remains the largest exporter to India, followed by Korea and Japan.

While India’s steel sector is progressing toward self-sufficiency with increased investments, improved quality control measures, and a focus on sustainable production, continued vigilance and strategic interventions will be necessary to reduce import dependency and boost domestic capabilities.