As the wheels of development and industrial progress turn, the inevitable byproduct is the generation of waste. The efficient management of this waste has become a matter of global concern. This has prompted countries to establish robust regulatory regimes that strike a balance between development objectives and environmental sustainability. India, a burgeoning nation, has embarked on a journey to address this critical issue. The country’s waste management landscape is governed by an array of subordinate legislations, overseen by the Ministry of Environment, Forest and Climate Change (MoEF), in collaboration with State Pollution Control Boards (SPCB) representing different states.

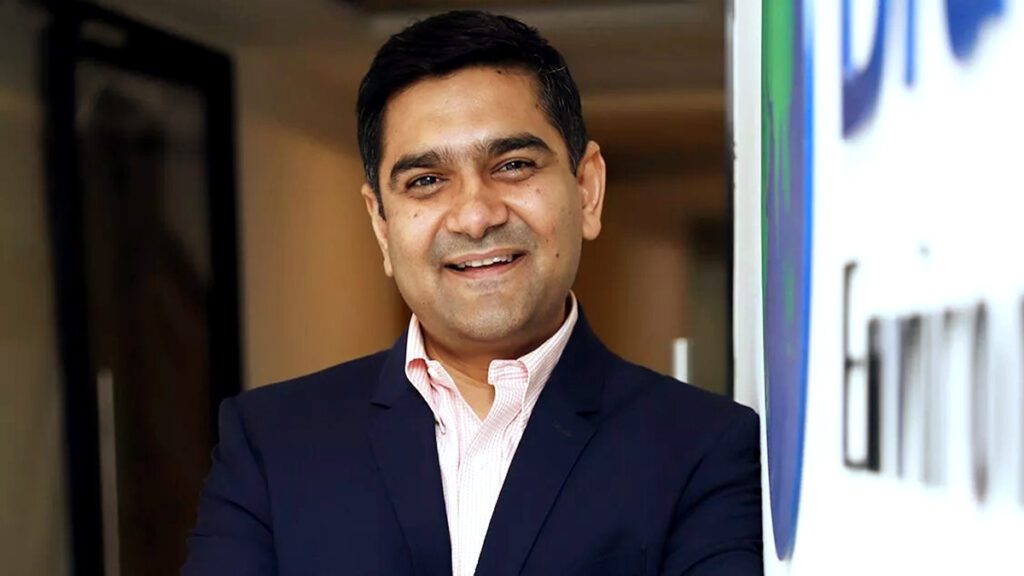

In this context, Prashant Singh, the Co-Founder and Chief Executive Officer of Blue Planet Environmental Solutions Pte Ltd, emerges as a pioneering figure. His focus is on constructing an integrated waste management platform that not only adds value to society, the planet, and stakeholders but also delivers a Net Positive Impact. In an exclusive interview with our Editor, Keshav Raina, Prashant shares his invaluable insights into the waste management industry and its pivotal role in addressing climate change.

Share your background as a waste management professional, including the path that led you to this career, and the driving factors that motivated your choice in this field.

I began my journey as a waste management professional in 2017 through the establishment of Blue Planet. I have resided in the US for almost two decades between 2000 and 2018. My experiences in various ventures, including consolidation and roll-up initiatives, led me to recognise the need for impactful environmental solutions. Motivated by a desire to address long-standing issues in an unprecedented way, Blue Planet emerged in 2017.

We primarily focused on regions where environmental challenges had not been effectively tackled before. Our vision encompassed transformative impacts on both the environment and society, along with our employees. Our operations commenced in Singapore and have since expanded to several countries, with India playing a pivotal role in our growth and achievements.

Tell us something about Blue Planet Solutions, its objectives in advancing regional sustainability through a comprehensive approach to waste management integration?

Blue Planet was established with an ambitious goal of achieving zero landfill waste. Traditionally, the waste management sector has seen multiple players involved in the value chain of waste’s journey from households to the landfill, resulting in fragmentation. When there are six owners to a problem, solving it becomes challenging. Our aim is to disrupt this approach by creating an integrated end-to-end waste management platform. We hold a core belief in upcycling. We view waste as a resource with untapped value that must be harnessed. This perspective aligns with the imperative of net-zero initiatives and addressing climate change by prioritising renewable energy and reducing the use of virgin materials. Our objective centres on establishing a robust sustainability and climate change platform that benefits stakeholders and the environment alike.

How do you maintain uniform service quality and operational efficiency across multiple countries where your presence is established?

Ensuring consistent service quality and operational efficiency across various countries is a crucial focus for us as an organisation. To achieve this, we heavily rely on technology-driven strategies. This technology encompasses waste upcycling solutions This includes as converting organic waste into biogas, plastic into fuel, and inert waste into block walls. Additionally, we prioritise establishing robust IT support on the backend. IT enables us to enhance traceability and trackability throughout the entire value chain. This distinct technological approach sets us apart in the waste management sector. It also grants us a competitive advantage as we expand our technology and services across different countries, while also fostering greater standardisation throughout our group.

Are your current operational locations limited to India and Singapore?

Our operations span across half a dozen countries. In Singapore, we operate as the holding company and manage over a third of the country’s waste. In India, we’re significant in landfill mining, having processed over 9 million tons of waste in the past five years. We have over 100 decentralised waste-to-energy plants in India. And a total of around 150 plants in15 different countries, we’ve established a significant global presence. Our physical footprint includes Singapore, India, Malaysia, Vietnam, the UK, and a partnership-based presence in Switzerland.

Can you provide details about the plastic-to-fuel technology you employ and the notable outcomes it has achieved thus far?

Our waste management approach includes a vital component: the plastic-to-fuel technology, which the Discovery Channel also showcased in the Planet Healers program. India is extremely efficient in terms of high-quality plastics such as HDPs and PET bottles, among other things. Our focus is on converting low-value plastics like multi-layer plastics (MLPs) and packaging materials, prevalent in landfills and local areas. Using thermocatalytic depolymerisation (TCD), we transform these plastics into a polyfuel. This polyfuel holds diverse applications, including substituting conventional fuels in incineration, as well as for rural use and LDO replacements. We’ve seen some decent traction in rural regions, which helps us close the loop on waste management for us. By converting plastic waste into a valuable resource, we address the challenge of long decomposition periods in landfills, simultaneously promoting environmental improvement and enhanced quality of life.

Your company is one of the largest suppliers of alternative fuels in India. Can you elaborate on the sustainable fuel solutions you offer and their role in mitigating carbon emissions?

We are among the largest alternative fuel suppliers in Asia, having surpassed 1.2 million tonnes of refuse-derived fuel (RDF) production. This RDF serves as a substitute for fossil fuels, primarily replacing coal. Our collaborations encompass 53 cement plants within India, while also exploring opportunities to export this technology to other countries. The significance lies in Government of India’s mandate, requiring industries with higher pollution impacts to manage their thermal substitute ratio (TSR) by incorporating sustainable fuel sources. Currently at 8%, discussions are underway to elevate this ratio to potentially 20-30%. This can lead to reduction in fossil fuel usage, decreased coal mining, and a positive long term climate impact. This endeavour plays a pivotal role in our commitment to contributing positively to global net-zero objectives.

In the RDF domain, the substitution of fossil fuels is the central focus of our efforts. We’ve formed key partnerships, including one with Vika Cement of France and Bharti Cements. These are for the establishment of co-processing plants that will provide high-quality RDF, which will be a first in India. Additionally, we’re exploring diverse applications for RDF upcycling, such as board and pallet production. The overarching goal remains upcycling and achieving zero landfill waste. At present, cement plants utilize RDF to replace fossil fuels. Enhancing the Gross Calorific Value (GCV) of RDF through granulation further diversifies its applications. We’ve piloted RDF-based board production for furniture and benches. Moreover, high-density RDF can serve as pellets, replacing virgin wood commonly used in transportation. We are exploring and actively implementing a multifaceted approach to maximize resource utilization, steering away from landfill disposal.

What is your opinion on plastic waste and the prohibition of single-use plastics? Does this stance intersect with your plastic-to-fuel technology?

Absolutely not. The increasing plastic waste generation in India, projected to grow 3-5 times over the next 20 years. It presents ample opportunities rather than challenges for us. We perceive the ban on single-use plastics as a positive step. However, the key lies in ensuring the availability of viable alternatives. The presence of alternative solutions, facilitated by governmental initiatives or contributions from industry players like us, plays a pivotal role in determining the effectiveness of such bans. Fostering innovative startups that can offer substitutes will determine the true impact of the single-use plastic ban. Filling that gap with alternatives is vital to assess how much impact we can create with the single-use plastic ban.

Can you provide information about the decentralised waste management plant in Greater Noida, its significance in driving local waste management practices, and it’s anticipated impact on the region?

We have built India’s first truly decentralised integrated waste management solution in Greater Noida. Covering 11,000+ households in one of the clusters in Greater Noida, it employs CNG vehicles powered by the waste they collect. Those 12 vehicles are equipped with proper segregation compartments for dry waste, wet waste, e-waste and domestic hazardous waste.

We provide Information, Education & Communication (IEC) activities to promote source segregation. Our facility processes collected waste, featuring technologies such as converting organic waste to biogas. We further scrub, clean, and channel this biogas into cascades along the pumping station, where it fuels the CNG vehicles. That’s a true circular economy solution as far as the CNG is concerned.

We have a plastic-to-fuel plant, a manure shed (byproduct of AD process), CBG plant and a domestic non-hazardous waste incinerator are also part of the site. This was conceptualised during the COVID period. The plastic to fuel output will be used as an input to run that incinerator. The end goal is the same as before. We process or upcycle more than 90% of the collected material in the stable stage somewhere, with only 10% being sent to the landfill.

This process of processing or upcycled, will result in 7,000 – 10,000 tons less landfill waste annually. Ultimately, more than 1,00,000 tons of waste will be diverted from landfills over 7 to 10 years. This approach minimises carbon emissions, decreases waste transportation distances. We have seen tremendous traction from municipalities and government to support this type of decentralised approach, which may not just reduce landfills and burden on landfills but also have a positive impact on our net zero journey.

What types of health and safety measures are implemented in your facilities, and how is automation integrated into your operations?

In India, our workforce varies depending at the time of year, between 1,500 to 1,800, and we are deeply committed to their well-being as well as social and financial inclusion. This is one area that is severely underserved in the sector because there are around 1 – 2 million workers in the waste management sector in India. But, we have yet to make a dent in their quality of life in terms of minimum wages and other such things. We recognise the underserved nature of the waste management workforce. We prioritise social and financial inclusion, ensuring dignified work conditions and competitive wages. For instance, in Sigma, one of the portfolio companies, we provide accommodations, three-time meals, and regular medical checkups for our employees.

These are the small steps we take to ensure that people connect with their job a little more than usual. This can only be accomplished if we offer them the respect and dignity that they deserve and that the sector has sorely needed.

We uphold strict safety protocols, providing proper protective equipment and regular training. Each site is equipped with ESG and EHS personnel to ensure compliance with environmental mandates. This is essential for us because if we take care of our people. The employees will take care of us as an organisation. We sincerely believe in it, and we have seen some extremely positive impact from our commitments to our employees.

Regarding automation, we blend our in-house R&D capacity with external solutions, customised to fit the Indian context. This approach enables us to incorporate innovative technologies and refine them for local application. It’s a combination of in-house capabilities as well as R&D and refinement. For example, in our landfill mining business, the first plant that we installed in 2016–17. It had a capacity of only 4 tonnes/day. Now, the same plant and machinery are operating at 1,000 tonnes/day. So we’ve been able to continuously refine our processes and outputs so that we can create a quality product out there.

With 17 completed bio mining projects, can you explain how this process aids in waste reclamation and environmental remediation?

By the time we share this data we would have already surpassed 20 landfill sites. This is particularly significant due to the SBM 2 guidelines and the commitment of our esteemed Prime Minister, Narendra Modi, to clear landfills in the coming 2 to 4 years. Policy support is strong, driving our efforts. We’ve also achieved substantial process standardisation.

It is basically divided into three parts. Firstly, pre-stabilisation, how do you pre-stabilise the waste by making windrows, by making sure it is ready for the processing. Secondly, segregation, where we build our own technology, developed and fabricated by indigenously in India. Lastly, the high quality of segregation allows us to dispose of waste and its by-products like RDF, coarse soil, fine soil, and more, in ways that contribute positively to projects. For example, let us say in Chennai, Tamil Nadu, India’s largest landfill mining project which just got completed. We collaborated with the Tamil Nadu Forest Department, using soil from landfills for afforestation. This initiative is compelling because it prevents landfills from persisting for decades. Instead, it contributes positively to the environment through our mining process.

We utilise this RDF for road construction and quarry filling, which holds significant importance. We’re also experimenting to enhance its quality, potentially for applications like sand mining. We have multiple new R&D initiatives in progress to maintain our primary objective of maximising the value derived from waste resources.

Where are your bio-mining projects located? Are they situated in urban areas, rural regions, or semi-urban areas?

The government’s efforts are directed toward clearing landfill sites across the board, including metros, tier 1 and 2 cities, as well as rural areas. However, the most significant impact can be achieved in tier 1 and metro areas due to their higher population density, resulting in exponential environmental consequences, both negative and positive. Last time I checked, there were over 2,800 landfill sites in cities with populations exceeding 1,00,000 and only a small fraction, around 5 – 10%, have undergone work to date.

There is a considerable need for progress and standardisation in the waste management sector. Waste management is a state subject, and differences in interpreting rules, guidelines, and processes can arise. Standardisation, especially in landfill mining, is crucial. For instance, ensuring that aggregates meet specified quality standards and comply with CPCB-approved limits for heavy metals, hazardous materials, and plastics is essential. Striking a balance between solving existing problems and avoiding the creation of new ones through robust compliance is vital on our journey to achieving net-zero goals. Focusing solely on a positive impact while being lenient on compliance could potentially lead to more significant problems for future generations.

What are your thoughts on the Ghazipur landfill? Can it be managed?

Certainly, it can be managed. Progress has been made, with government tenders issued and efforts underway at the Ghazipur landfill site. However, the crucial point to emphasise is not just making the landfill disappear but doing so in a sustainable and compliant manner. The focus should be on ensuring that the resolution is not just about elimination. It should also be about conservation for future generations. It’s imperative that the relevant authorities play a significant role in this process. They must prevent companies from compromising on compliance and the quality of aggregates that are disposed off in nearby areas. It potentially creates more significant problems for future generations.

What has been your contribution to the Sustainable Development Goals (SDGs)?

The Sustainable Development Goals (SDGs) have been our guiding force from the outset, and we directly and indirectly contribute to 15 out of the 17 SDGs in various capacities. We view these goals as a valuable guiding framework for any company, ensuring that our operations align with them and result in tangible, measurable positive contributions. We hold a high commitment to the SDGs and believe in their significant impact, which makes a positive difference across our entire value chain.

What are your hopes for the upcoming COP28?

Regarding COP28, we hold great optimism, particularly for countries like India and other developing nations. The most significant challenge, in our view, will revolve around transition financing. This challenge includes questioning how to facilitate the shift towards renewables, how to adopt new technologies customized for our region, and how to financially support this transition. For a country like India, projected to sustain growth at 6-8% over the next two decades. While simultaneously committing to achieving net-zero emissions by 2070, it represents a very powerful statement and commitment from the Government of India. The journey ahead involves a delicate balance between sustaining the growth of a developing nation. This includes ensuring fulfilment of net-zero commitments—a very interesting balancing act that we need to do as a country.

What is your perspective on the issue of waste segregation? Despite awareness campaigns, many people do not segregate their waste before disposal. How do you believe this behaviour can be altered or improved?

Addressing the behavioural change towards waste segregation is a crucial challenge in our sector. When I relocated back from the US, we were segregating waste very passionately. But the moment the lady came to pick waste in the morning, in front of my eyes, she used to put everything in one bag and afterwards where it ends up, no one knows. Building an ecosystem for segregated waste collection is vital; otherwise, the purpose is defeated from the start. It is our goal to build that ecosystem through our Greater Noida plant.

Once we establish this ecosystem, the next step is government-mandated enforcement of source segregation. It’s the responsibility of municipalities to ensure regular segregation through Information, Education & Communication (IEC) activities. We work closely with municipalities to promote source segregation, engaging in IEC activities and outreach to schools and colleges. Our ‘Blue Nudge’ program is aimed at educating young individuals. It covers students from fourth to twelfth grade and first to second-year college students on source segregation, sustainability, climate change, and waste management.

We’ve already reached over a million students in the Delhi NCR region. Our goal is to extend this initiative to 10 million students over the next 4 – 5 years. By doing so, we aim to create a profound impact on source segregation awareness. Knowing that when these students return home, they can influence change in their households.

Despite segregating waste at home, waste collectors often mix it all together when they collect it. How do you believe this practice can be changed or improved?

The primary driver for change lies in building a comprehensive ecosystem with a strong emphasis on waste processing. Discipline in processing is essential because it’s where the focus on waste quality can be most effectively applied. Technology plays a vital role in this process by ensuring that certain materials, like plastics or inorganics, don’t hinder processes, such as biogas production. We need to bring people to see this is how it negatively impacts the process. If you don’t segregate, what happens to the waste. However, we still need to make much progress in terms of adopting technology. This will help alleviate pressure on landfill sites by diverting waste from them.

Do you believe that establishing waste collection facilities similar to the bottle collection plant in CP (Connaught Place) can be implemented in urban household areas?

Households might be challenging, but focusing on bulk generators, such as residential welfare associations (RWAs), is a feasible approach. Comparing cleanliness and sanitation with developed countries often overlooks the differences in awareness and commitment among consumers in our country. We often draw comparisons with developed countries regarding cleanliness and sanitation. We must also consider the significant differences in awareness and commitment among consumers in our country.

In the future, as we establish a sustainable waste management ecosystem, the concept of ‘polluters to pay’ will likely need to be enforced in India. This means that if individuals fail to segregate and dispose of their waste correctly, it should come with a cost. This approach would contribute to the financial sustainability of waste management systems. This is similar to practices in developed countries where consumers support these systems, financially. Given the anticipated growth in waste generation over the next 10-20 years, solving this issue on a commercial level is essential, as the waste management industry requires substantial capital investment. Attracting the right funds and capital is critical, alongside addressing environmental, social, and governance (ESG) aspects.

Do you think that imposing penalties on individuals who litter on roads would be effective in making a difference in India?

India has traditionally employed a combination of incentives and penalties, often referred to as the ‘carrot and stick’ model. However, in this context, imposing penalties should be seen as a phase three approach. It’s crucial for concessionaires, government entities, municipalities, and all stakeholders to first collaborate on building the right solution and fostering the necessary ecosystem. Afterward, gradual reinforcement and support for this ecosystem can be introduced. Eventually, the third step could involve implementing penalties for non-compliance once the ecosystem has matured. Penalties will be considered when individuals have been given ample time and we have conducted awareness campaigns (IEC), yet they continue to disregard the rules. However, it’s essential to recognise that before reaching this point, there is a substantial journey ahead to ensure that the entire ecosystem is at a stage where it effectively supports and justifies the implementation of penalties for non-compliance.

Landfill sites are significant sources of methane emissions. Is it feasible to capture and store this methane for utilisation?

Methane, which is 21 times more harmful than carbon dioxide, presents a significant environmental challenge. Landfills are unfortunate contributors to methane emissions. Certainly, methane capture is an area worth exploring. Several projects in developed countries have experimented with it. Our organisation is currently conducting a pilot project on methane capture with the aim of finding ways to collect, store, and utilise methane for more beneficial purposes rather than releasing it into the environment. We anticipate being able to offer a solution to our customers in India within the next year.

Are there any upcoming projects or R&D initiatives from your organisation in India?

One of the significant challenges in India is source segregation, and it will take time to build the necessary capacity and capability for waste segregation in-house. Customising waste segregation technology to suit the unique characteristics of Indian waste streams is a critical aspect. For instance, Indian waste can vary widely in moisture content, from 30% to as high as 80-90% during the rainy season. It’s essential to refine machines to address these challenges effectively. Another crucial aspect is upcycling, focusing on creating better solutions for the raw materials obtained. This can lead to longer usability and extend the lifespan of these materials, such as improving the quality of soil for topsoil replacement or afforestation purposes.

These are the concrete and significant impacts we are making on the environment and the lives of people in general. We have multiple ongoing R&D activities, and as for RDF, it presents a substantial challenge and opportunity for the industry. By continuously refining and improving solutions related to RDF, we can expand its impact. This might become one of the first instances where an indigenous waste management technology developed in India has matured to a level where we can export it and apply it in developing and developed countries.

We are exploring opportunities in countries like Malaysia, Vietnam, the UK, and Europe. Leveraging our landfill mining business, we believe we can make a substantial positive impact in these regions.

How much energy is generated by your company across India?

The energy generation is a result of most of these plants being owned by our customers because we sell them as a product through an EPC model. Unfortunately, we don’t have access to their data. However, through our journey, we’ve observed that we process nearly 25,000 tonnes of waste daily across the five or six countries we operate in. To date, we’ve processed over 11 million tonnes of waste and prevented approximately 6 to 7 million tonnes of CO2 emissions from entering the environment. Our goal by 2030 is to reach between 30 to 40 million tonnes of CO2 emissions avoided, which accounts for about 3 to 4% of our nation’s commitment to avoid a billion tonnes of CO2 emissions. This represents a significant positive impact and contribution to the environment.

What are your views on carbon credits?

Carbon credits are crucial for our infrastructure projects, especially in supporting larger-scale initiatives in waste management and addressing climate change. India has recently introduced an initiative to develop a market or ecosystem for carbon credits. It’s still in its early stages. And it would be highly encouraging if this initiative evolves to meet global standards. However, it’s essential for policymakers and compliance mechanisms to introduce rigorous frameworks. This will ensure the legitimacy and trustworthiness of these carbon credits.

The traceability and trackability, as I mentioned, are of utmost importance. They will enable us to expand our efforts and compete effectively in the global market. Authenticity and the ability to validate and verify carbon credit data are crucial. This will enable us to obtain the correct value for these credits. Without proper traceability and trackability in a scientifically sound manner, we risk missing out on a significant opportunity. The value of carbon credits can vary greatly, and it’s essential to get our processes in order in this regard.

Are there areas in government policy that could be enhanced to further support and foster growth within your sector?

Absolutely, I believe that the progress we’ve achieved in the past 7-8 years has placed us on the right path. We’ve seen policy developments such as the SBM 2016 rules, the 2019 addendums, regulations on e-waste, plastic waste, and more. The introduction of SBM 2.0 last year has also been a positive step, with several beneficial policy interventions.

We should be aware that there is a need to create favourable conditions for the sector for substantial impact. While there has been significant focus on renewable energy, particularly in the realm of electricity through solar and wind energy, there is a substantial growth opportunity in municipal solid waste. Over the next 20 years, this waste is projected to increase from 60 million tonnes to 150 million tonnes. This presents a tremendous resource potential. Without standardisation and the implementation of best practices, there is a risk of losing out not just for the sector but for the nation as a whole. Today, we seek alternative resources beyond traditional renewables like solar and wind. However, we must explore mechanisms for utilising this feedstock to bridge the gap.

Do you think, installation of compressed biogas plants (CBG) in urban areas in India could potentially lead to a reduction in the country’s LPG imports?

Absolutely, the objective is indeed to reduce our reliance on natural gas imports. This can be done by developing the Centralised Gas Grid (CGD) infrastructure. We have made significant investments in this area. We are collaborating with both PSUs like Indian Oil, BPCL, and HPCL, as well as private players such as Adani and Reliance. This represents a substantial transformation for the sector. Our goal is to decrease dependence on imported natural gas, and for this reason, we are enthusiastic about Compressed Biogas (CBG). We are continually enhancing our capabilities and capacity for CBG through a Centre of Excellence within our company. We are dedicated to improve both production efficiency and minimising losses to contribute to the national CBG objectives.

As the CEO of Blue Planet, what aspects of the company’s mission and achievements personally inspire you the most based on your experience? Additionally, do you have any plans for taking the company public in the future?

The remarkable progress we’ve made, from our initial journey to where we are today, is truly inspiring. This progress encompasses our tangible impact on the ground, our growth prospects, and the development of our in-house technical capabilities. What keeps me motivated is our commitment to scaling up our positive impact and our unwavering passion for the work we do. We constantly seek ways to do more and expand our reach. For instance, in the landfill mining sector, we are already one of the largest players in India, but we don’t intend to stop there. We aim to leverage our expertise and experiences to benefit other countries. Importantly, we recognise that this isn’t a one-person show; it requires collaboration with all stakeholders.

Building a larger, well-organised ecosystem involving more people and structured players allows us to collectively generate a greater impact. Personally, what motivates me the most is the potential for positive impact.

Regarding our future, while going public with an IPO is a possibility we will consider, it’s important to note that this sector requires patience. We must ensure tangible progress and avoid the mistakes made by others in the past. Our approach is to be patient, proceed steadily, make incremental advancements, and then evaluate our options. This could include an IPO or continued expansion into new regions, among other possibilities. We are highly optimistic about our organisation’s future. We’ve garnered significant interest from global players who want to support our journey, given the commitments and policy reforms in the sector. There is immense potential ahead, and we believe we are just beginning to tap into it. The journey is still ahead of us.

Is this Waste Management sector profitable?

Indeed, profitability is a core principle for us. We adhere to the philosophy of a net positive impact, encompassing the triple bottom line approach. This means creating a positive impact on the environment, engaging with people, and as an organisation. Generating returns for our shareholders and stakeholders is vital, as it allows us to scale our business and expand globally, thereby making a more significant and lasting impact. Our organisation’s ethos is centred on achieving a net positive impact through the triple bottom line philosophy. Profitability is essential to maintain the trust and support of our current shareholders and attract new investors, ensuring a sustainable growth trajectory.