Waste is a part of our daily life and mostly, we don’t even know where our waste will end up in. It could end up in a landfill, a water body or a WTE Plant. Our primary goal is to get the waste out of our homes or immediate possession as soon as possible. Its very easy to overlook the environmental impact of irresponsible dumping. Masood Mallick, Joint Managing Director, Ramky Enviro (REEL) in an exclusive interview with Energy Asia gives an insight on Waste to Energy sector in India, challenges he faced during COVID, recycling of bottom ash and how WTE can lead towards sustainable living.

Not everyone aspires to be a waste recycler. What prompted you to come into this field?

I think foremost reason is the scale of this problem. Look at what is happening around the world with population growth, increased consumption, urban development and magnitude of resource consumption. Mountains of waste is crowding almost every city in the world. Ghazipur landfill today is higher than Qutub Minar. This is a huge problem. On the other hand, it is a huge opportunity as well. This mountain also represents immense value in terms of resources that it contains. Despite this, we most of the times are mining for similar resources, destroying forests to mine, importing from other countries and spending foreign currency.

Today, this mountain of waste is like a huge problem staring at us. It is making living more unsustainable and increasing public health risks. I think that it is an existential problem, just like climate change. It is a significant problem for any developing economy to solve. As environmental professionals, we don’t think there is a bigger problem in the world to solve. We have the vision or ambition or stupidity to go after big problems. We think that the environmental, social and the economic impact of solving this problem is remarkable. That is the reason why we are here.

The concept of waste recycling as the ‘Kabari Wala’ is also changing. In future, the erstwhile ‘Kabari Wala’ is going to be an important part of the value recovery chain. Whether he is picking it or we pick it directly, it doesn’t matter. What matters is, what happens with it afterwards. Afterwards, it’s not ending up at Bhalswa or the Ghazipur dump sites. It is processed to take out to various components,explore ways to find value in each of those components. Afterwards, these components are put it back into the manufacturing.

Waste segregation is a major challenge in India. Due to unsegregated waste most plants in India are not performing up to the mark and in turn incur heavy losses. How are you tackling/planning to tackle the issue?

I think one of the biggest problem for waste management and recycling is lack of segregation, no doubt. We are working relentlessly on this. In Chennai, we are leveraging multiple channels of communication and social engagement to create a buzz around waste segregation at source. Unlike the west or Japan model where people segregate materials in seven different bins, we are making it very simple. We are saying Gila (Wet) and Sukha (Dry), that’s all. There is no complication of recyclable waste or non-recyclable waste.

We are making it a social campaign driven by children in schools, like the Diwali Crackers campaign. The Diwali Crackers campaign had a huge impact. It created such a big change, when I was a child, it was like who will burst more crackers. Today, people feel guilty while bursting crackers. This is the power of communication and information, using the right channels to the right target communities gives immense success. In addition to schools, we are also engaing with educational institutions, NGOs, local influencers, actors and performers to spread this message.

As a result, we have up to 65% source segregation in Chennai. Bringing a change around segregation at source is challenging. It’s a very grassroot thing and it cannot be done by putting pamphlets and banners. It took 15 years for Europe to segregate waste at source, but we don’t have that much time. However, I think if we can reach 65% source segregation in Chennai in six months, we have hope.

How are you working to make electricity generated from WTE plant cost effective compared to other renewable sources?

I would actually say that to visualize WTE as an energy source is not the right way to look at it. It is not an energy source, it’s a waste management technology like composting. You manage waste by making compost from it. Well made compost is a good substitute for Urea, which has much worse environmental impact. This methodology not just prevents creation of another Ghazipur waste mountain, but subsitutes a resources like urea, which is created by chemical process. Cost of composting cannot be compared to Urea, compost is waste management.

Likewise, we are managing the waste by generating energy. The purpose is to take good amount of waste which otherwise would have created another waste mountain and minimise it. Whatever left of it is also recycled, so that nothing goes to landfill and during the process, power becomes the by-product. It is nit just an energy source.

The cost involved in this process is towards waste management, not power generation. We are not competing with solar power or thermal power. We are basically reducing the cost of waste management by generating some power. If you look at India’s energy mix, Waste to Energy is not even 1%. What is inherent in Waste to Energy tariff is that, it actually is an environmental cess. It is just the cost of waste management. Therefore, to see it as a source of cheaper power supply is completely wrong. We are just generating power to manage trash which would have otherwise gone to landfills. Thousands of crores of rupees are spent on landfills, which are highly unsustainable and unhealthy. If I am able to recycle all that waste and also able to generate some power, then it’s a win-win situation.

Cost of power generated by WTE is very high. Why would DISCOMs purchase at a higher price?

If you look at the WTE policy, government knew that DISCOMs who are already in red, would never willingly purchase power at such a cost. WTE technology takes thousands of tons of waste and practically disappears it . This cost of conversion is being offset by the cost of power. WTE Policy says if Waste to Energy (WTE) if available, the DISCOMs have to buy power from WTE Plants. Central Electricity Regulatory Commission (CERC) has issued guidelines on how tariff will be determined.

Today capital cost of Solar Power Plant is around ₹4 Crores per megawatt (MW) whereas Waste to Energy (WTE) Plant costs 22 to 25 crores per megawatt (MW). How can the tariff be the same? How can I compete with those guys? All I’m saying is that I have no interest in generating power. Setting of WTE plants become a compulsion for me as there is no land. The piece of land goes forever if landfill is constructed on it. Nobody will be able to recover it after that.

You have to look at the whole life cycle cost here. Usually big urban centres in developed countries like Europe and Japan have WTE plants due to high cost of land and lack of alternatives. You need to reduce the base mass of waste and therefore you burn it. However, you must ensure burning does not lead to any environmental impact. So, one of the ways to burn it without creating environment impact is to make power from it.

Did you face any challenge in segregating hazardous waste after COVID? Generally, how do you ensure good health of your work force?

Luckily, Ramky as a company, for its industrial division handles about 1 million tons per annum of hazardous waste. We already had a network where we were managing hazardous waste from 35,000 health care establishments. When COVID waste started shooting up six times, CPCB permitted to use those industrial hazardous waste facilities to manage COVID waste.

To manage waste amidst COVID, we created separate corridors where whole blue chain became normal hazardous waste and yellow chain became COVID waste. We created yellow chain in all of our industrial facilities. We already had 20+ biomedical facilities which were all dedicated to COVID waste. In addition to that, incinerator which processes bio medical waste often have capacities of 250 kg per hour, 200 kg per hour or 100 kg per hour. But our industrial incinerator is 1.5 Ton per hour. When waste generation went up six folds, we already had captive capacity in our industrial plants. We used that capacity for biomedical waste and handled waste of every generator, even if they were not sending to us. At that time, we didn’t sign any agreement, we accepted COVID waste from everyone.

In our yellow corridor, dedicated vehicles were picking up the waste with dedicated staff with dedicated SOPs and dedicated precautions. At first, we were utilizing our existing biomedical facilities. When it was maxed out, the remaining waste went to industrial facilities. This kind of network is across the country . We are actually lucky to be a pan Indian company, so we can utilize the resources.

Where we saw the infectious waste is getting mixed with municipal waste, we intervened with the municipality. As a result, municipalities started segregated collection in many cities. Segregated collection from the designated isolation centres was separate, normal waste collection procedure was not followed. Across India, the e designated COVID isolation areas & red zones in the bigger municipalities were able to segregate. They recognised that this is going to be a bigger problem. But we couldn’t segregate household waste.

If one mask has gone inside the waste bag, that whole bag is COVID waste. This is the law. If you have cross contamination of waste, the most hazardous component defines the classification of that bag. If we spot any suspicious COVID waste, we designate it as COVID waste. Even if it isn’t COVID waste, who will take a risk, I can’t. We called this as the precautionary principle. If you’re not sure about something, apply the most conservative definition to it.

Our people who handle infectious materials look like astronauts. We make sure they have the right gear, PPE, training and medical surveillance. They’re checked very frequently. So are training, standard operating procedures (SOPs), personal protective equipment, full body and medical surveillance. These are the four methods that we have to ensure for health of our people. We had 290 something cases of COVID within 20,000 people, much lower than the national average. And we were the frontline workers, we were collecting waste even when lock down was imposed. None of our 1,500 waste collectors contracted COVID.

Been working in India as well as overseas, do you see any difference or challenges in working in India as compared to other countries?

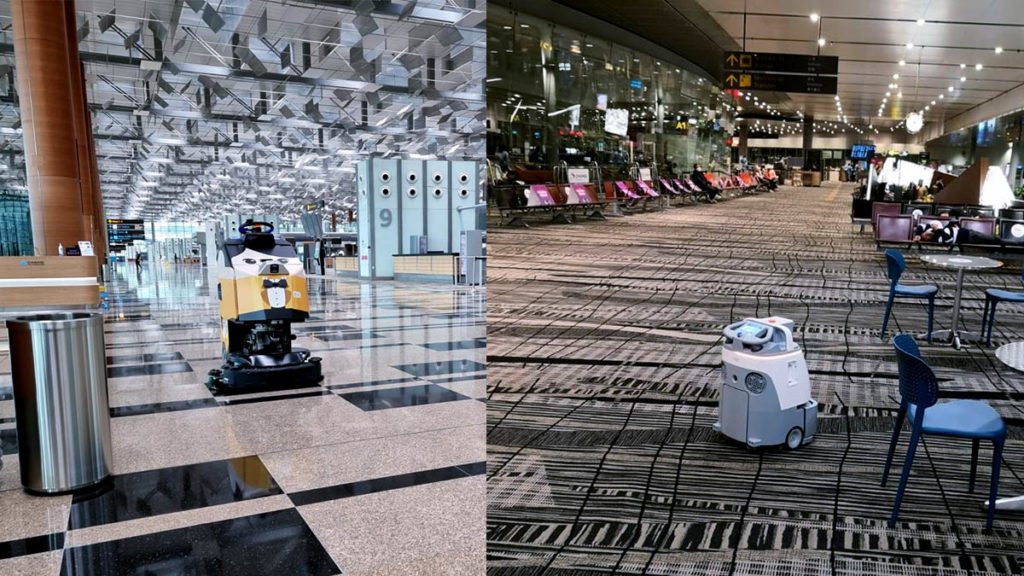

Ramky operates in Singapore, India, across the Middle East and North America. Every location brings a new opportunity to learn. In Singapore, the environmental and sanitation standards are at a different level. Their approach is towards total sanitation, everything is performance based.

Ramky Enviro is proud to be the company that keeps Changi Airport clean. It is the best and cleanest airport in the world. We have learned how to perform to that level of sanitation standards. I have worked with the National Environment Authority of Singapore in public waste collection. I also keep a part of Singapore clean. Knowing the ways, means, methods and technologies to deliver waste management, cleaning and sanitation services to Singapore standards taught us a lot as a company. Today, our presence in Singapore is not small, there are 2,500 people working for us. It’s a matter of pride, actually. By operating in Singapore, we learnt better quality standards and automation. When you go to Changi next time, you will see little robot running around and cleaning. The level of automation is different robotics and technology.

Is it directly applicable to India? No. But as a company to have that exposure, learning and that capability is extremely important. On the other hand, in Middle East, we are taking learnings from India and applying them to solve problems. We learnt being efficient and localisation of technology from India .The amount of technology localization that we have done and efficiencies we have, the so called western companies cannot even think of. They cannot compete with us because of our localized indigenised technologies. These technologies offer much better value and higher efficiencies, including cost efficiency. It is the key to our success in Middle East.

We ventured in marine waste field in North America. Marine waste is a big thing of the future. We wanted to get into marine waste recycling. We are just commissioning the first marine waste recycling facility in Oman. That is how we synergize, learn and apply. And that’s why it is so important to have presence in both developing economies and our biggest market-developing economies. We learn from economies like Singapore and North America and apply it backwards.

With rapid urbanisation the amount of landfill is also growing exponentially. How many WTE plants do you think should be commissioned in coming time to reduce the landfills considerably?

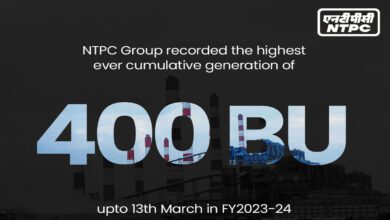

China already has more than 500 and is constructing 800 right now. We have only five, there is a long way to go. Currently, we are at approximately 50 MW. We have another 100 MW in construction and 400 MW in development. Currently, we have in line of sight of going up to 550 MW. We have a city by city survey on WTE potential of India. I can tell you that this sector can easily grow 100 times and it needs to grow 100 times. It is not the solution for every city. But if you look for big cities and land constrained regions with higher population density, you have no option except WTE. We have just announced western India’s first WTE Project in Deonar Landfill.

How much waste is processed by your plants and its energy output every day?

Currently we have 44 MW daily generation capacity and around 0.95 million units power is generated per day. In terms of waste processing, we handle around 13,000+ tonnes of Municipal Solid Waste, 2,900 tonnes of Industrial Waste and 150 tonnes of Bio Medical Waste per day. Round about, it comes around 7 million tons in a year.

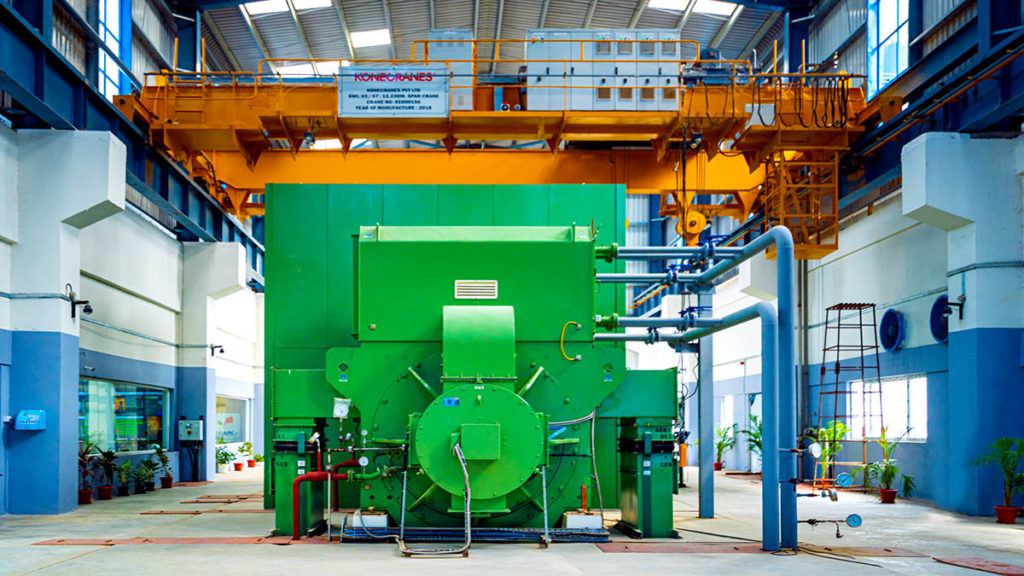

Our Hyderabad plant’s capacity is 20 MW, but its operating at 100% plus Plant Load Factor (PLF). It’s one of the most advanced plant in the world and we are very proud of it. Hyderabad’s fuel is very good, that’s the main reason for 100%+ PLF. When we designed our plants, we remember our learnings from Delhi. Delhi has the worst waste, it’s horrible. Our learnings from Delhi were vital while working on Hyderabad plant.

Environmental groups have long protested on WTE plants as it can lead to health risk, especially bottom ash. How do you dispose off bottom ash to minimise health risk?

Amongst our several plants, Delhi plant is the largest in India with a capacity of 24 MW. We analyse every batch of bottom ash and recycle it fully. What do I make from it? I make road aggregate and tiles, so there is no bottom ash. The 10% ash which is left after waste combustion, I recycle that too, so nothing goes to landfill. It’s the first time in India that bottom ash recycling has been done successfully, at scale. It’s a full scale, fully automatic plant with multiple stages to process bottom ash where it is recycled and made into products.

How has Swachh Bharat Mission impacted the Waste to Energy sector?

I think during the Swachh Bharat 1.0, the focus was obviously on Open Defecation Free (ODF) and collection of waste. A lot of cities focused on collection of waste. We benefitted from that. We worked with the government to ensure that we put in world class collection systems. The focus of Swachh Bharat 2.0, is processing and treatment of waste. And I think that is really going to be a game changer for this sector.

Right now, most of the municipalities are spending their money in just transportation of waste. A big chunk of waste management spending is towards transportation. This focus will shift towards processing of waste and resource recovery. That is the part we are really excited about from Swachh Bharat 2.0.

What are your thoughts on 2022 single use plastic ban?

Single use plastic is a real problem. I look at this whole issue in two ways. The plastic consumption per capita is only going to grow in India. We will be consuming more and more plastic every year. How do we ensure that this plastic that has a lower environmental footprint as compared to the previous year? One of the ways is to take out as much of single use plastic from the ecosystem as possible.

On the other hand, we have to be ready as a country and as waste managers to collect, segregate and process more plastic than ever before. Whilst you through legislation, you can reduce single use plastic, the amount of plastics overall will grow. However, plastics will have higher reuse and recyclability opportunity. If you look at the hierarchy of waste management, you first reduce, then reuses and recycle at the end. We should make products with longer life. iPhones are made to last only one year, which earlier was a three year cycle. How do you create longer life of resource and once it reaches its end of life, how to recycle and recover resources from it? That is really the heart and soul of what we think every day.

How are you working towards Decarbonisation?

We have a huge decarbonisation goal. Our business operations, power consumption, fuel consumption has a carbon footprint. However, these operations help us in preventing other carbon emissions.

A waste, if we had not managed through WTE plant, that would have created Methane, which, now it converts into carbon dioxide. One ton of carbon dioxide has much lower GHG potential compared to one ton of Methane, which has 25 times higher GHG impact. One ton of methane is equivalent to 25 tons of carbon dioxide. By avoiding methane generation, we are reducing carbon footprint of that waste 25 times, that’s called avoided emissions. Our avoided emissions are many times higher than our carbon footprint. We are in a carbon negative business. But, we want to reduce my own carbon footprint also. We aim to achieve net negative carbon footprint by 2024.

This year, we added 850 in electric vehicles to our fleet. Being one of the largest fleet operators, our goal is to turn 50% fleet to electric. You cannot call yourself an environmental company without an internal decarbonization strategy. We are going gangbusters on decarbonisation.