Vishal Gupta, Co-Founder-Maxvolt Energy

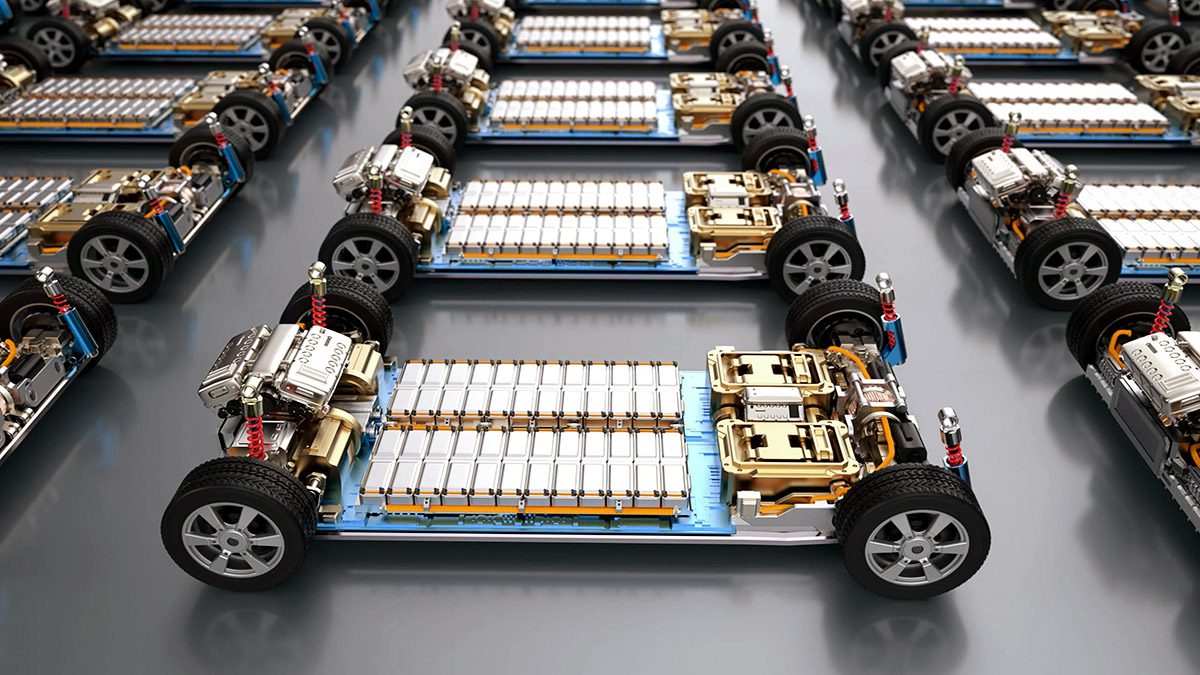

Since their introduction in 1991, lithium-ion batteries have emerged as the dominant force in the market, primarily due to their superior energy density and efficiency. These batteries are particularly well-suited for portable electronics and electric vehicles, offering significant advantages in energy storage, life cycle, and weight over traditional lead-acid batteries. While the widespread industrial adoption of lithium-ion technology is critical to reducing reliance on fossil fuels, addressing challenges related to safety and longevity remains essential. Thus, continued innovation and strategic advancements are necessary to ensure that lithium-ion batteries can meet the increasing demands for both technological progress and sustainable energy solutions.

Addressing Safety Concerns

One of the most significant concerns surrounding lithium-ion batteries is safety. These batteries are prone to thermal runaway, a chain reaction that occurs when the battery’s internal temperature rises uncontrollably. This may result in overheating, fires, and even explosions in exceptional cases. Such incidents, while rare, have raised alarms in industries reliant on lithium-ion technology, particularly in electric vehicles (EVs) and consumer electronics.

Several factors contribute to the safety risks of lithium-ion batteries. One is the flammability of the liquid electrolyte used to transport lithium ions between the battery’s electrodes. Another is the potential for internal short circuits caused by manufacturing defects, mechanical damage, or the growth of dendrites—tiny, needle-like lithium formations that can pierce the battery’s separator and cause a short circuit.

To address these risks, researchers and manufacturers are developing a range of safety-focused innovations. One promising approach is the use of solid-state electrolytes. Solid-state batteries replace the traditional liquid electrolyte with a solid material, reducing the risk of fire and thermal runaway. These solid materials are also more resistant to dendrite formation, which further enhances safety. In addition to solid-state technology, the development of more robust battery management systems (BMS) has been instrumental in improving safety. BMS monitors a battery’s performance in real time, detecting potential issues such as overcharging, overheating, or abnormal voltage levels. Advanced BMS software can adjust charging rates or cut off power to prevent dangerous conditions, significantly reducing the risk of thermal runaway.

Addressing Longevity Challenges

While safety remains a top priority, longevity is another critical concern for lithium-ion batteries. The degradation of batteries over time limits the lifespan of products like electric vehicles and consumer electronics, and it can hinder the viability of renewable energy storage solutions. Battery degradation occurs due to factors such as repeated charging cycles, high operating temperatures, and the gradual breakdown of materials within the battery.

To combat this, researchers are exploring new materials and designs that can extend the lifespan of lithium-ion batteries. One such innovation is the use of silicon anodes instead of traditional graphite anodes. Silicon has a higher capacity for lithium ions, allowing batteries to store more energy and last longer. However, silicon expands and contracts significantly during charging and discharging, which can lead to material degradation and battery failure. To address this, scientists are developing nanoscale silicon structures that can accommodate these volume changes without breaking down.

Another promising approach is the development of advanced electrolyte formulations. Researchers are working on electrolyte additives that can form protective films on battery electrodes, reducing degradation and improving performance over time. These additives can also help reduce the growth of dendrites, further enhancing both safety and longevity.

Assistance from AI and ML

Artificial intelligence (AI) and machine learning (ML) are increasingly playing a role in improving the longevity and safety of lithium-ion batteries. AI-driven algorithms can analyse vast amounts of data from battery performance, identifying patterns and predicting potential failures before they occur. This predictive maintenance can help extend battery life and prevent safety incidents by ensuring batteries are operated within safe parameters.

AI is also being used to optimise battery designs and materials. By simulating different material combinations and battery structures, researchers can accelerate the development of more durable and safer batteries. This approach is particularly valuable in the search for next-generation materials that can replace or enhance current lithium-ion technology.

Adherence to Regulatory Compliance

In addition to technological developments, vehicle components, particularly battery pack systems, must undergo rigorous testing to meet regulatory compliance standards. These include stringent international safety standards, mechanical shock, vibration, thermal cycling, and electrical abuse tests. OEMs must also adhere to geography-specific regulations like AIS 048, ECE R100, UN 38.3, or ISO 26262. Understanding compliance for functional safety standards is crucial for OEMs and service providers to ensure safety under various conditions.

Embarking on Innovative Future

Innovations in solid-state technology, new materials, and AI-driven optimisations are paving the way for the next generation of energy storage solutions. As these technologies mature, we can expect to see significant improvements in the safety and longevity of lithium-ion batteries. These advancements will not only enhance the performance of electric vehicles and consumer electronics but also play a crucial role in enabling a more sustainable energy future.